Scientists using new 3D printing technology have produced lithium-ion batteries the size of a grain of sand. They say the tiny batteries, similar in function to those in cell phones and digital wristwatches, could be used in a new wave of innovative, miniature medical devices.

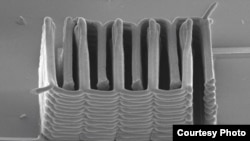

Teams from Harvard University and the University of Illinois at Urbana-Champaign used 3D printing techniques to interlace minute battery electrodes, each less wide than a human hair.

“Not only did we demonstrate for the first time that we can 3D-print a battery; we demonstrated it in the most rigorous way,” said Jennifer A. Lewis of Harvard, senior author of the study. Lewis is the Hansjörg Wyss Professor of Biologically Inspired Engineering at Harvard’s School of Engineering and Applied Sciences (SEAS).

The tiny batteries could bode well for medical devices such as implants, minute robots, tiny cameras and microphones, which currently need batteries as large, or larger, than the devices themselves.

Miniature batteries have traditionally been made of thin films of solid material. Due to the thinness, the batteries were not able to hold enough energy to power devices of the future. The use of 3D printing provided the opportunity to stack layers of materials capable of storing much more power.

The first hurdle to overcome was to develop a specialized ink. The 3D printers, instead of releasing liquid droplets like a typical inkjet printer, release ink through fine nozzles like toothpaste from a tube. The ink also needed to function as electrochemically active material to form the battery’s anodes and cathodes and also to immediately harden.

The printer deposited the inks onto the teeth of two tiny gold combs, creating a tightly interlaced stack of anodes and cathodes. Then the researchers packaged the electrodes into a tiny container and filled it with an electrolyte solution to complete the battery.

“The electrochemical performance is comparable to commercial batteries in terms of charge and discharge rate, cycle life and energy densities. We’re just able to achieve this on a much smaller scale,” said co-author Shen Dillon, an Assistant Professor of Materials Science and Engineering at the University of Illinois at Urbana Champaign.

The microbattery ink designs “open up entirely new possibilities for miniaturization of all types of devices, both medical and non-medical,” said Donald Ingber, who is also a Professor of Bioengineering at Harvard SEAS.

The results have been published online in the journal Advanced Materials.

Here's a short video about the process:

Teams from Harvard University and the University of Illinois at Urbana-Champaign used 3D printing techniques to interlace minute battery electrodes, each less wide than a human hair.

“Not only did we demonstrate for the first time that we can 3D-print a battery; we demonstrated it in the most rigorous way,” said Jennifer A. Lewis of Harvard, senior author of the study. Lewis is the Hansjörg Wyss Professor of Biologically Inspired Engineering at Harvard’s School of Engineering and Applied Sciences (SEAS).

The tiny batteries could bode well for medical devices such as implants, minute robots, tiny cameras and microphones, which currently need batteries as large, or larger, than the devices themselves.

Miniature batteries have traditionally been made of thin films of solid material. Due to the thinness, the batteries were not able to hold enough energy to power devices of the future. The use of 3D printing provided the opportunity to stack layers of materials capable of storing much more power.

The first hurdle to overcome was to develop a specialized ink. The 3D printers, instead of releasing liquid droplets like a typical inkjet printer, release ink through fine nozzles like toothpaste from a tube. The ink also needed to function as electrochemically active material to form the battery’s anodes and cathodes and also to immediately harden.

The printer deposited the inks onto the teeth of two tiny gold combs, creating a tightly interlaced stack of anodes and cathodes. Then the researchers packaged the electrodes into a tiny container and filled it with an electrolyte solution to complete the battery.

“The electrochemical performance is comparable to commercial batteries in terms of charge and discharge rate, cycle life and energy densities. We’re just able to achieve this on a much smaller scale,” said co-author Shen Dillon, an Assistant Professor of Materials Science and Engineering at the University of Illinois at Urbana Champaign.

The microbattery ink designs “open up entirely new possibilities for miniaturization of all types of devices, both medical and non-medical,” said Donald Ingber, who is also a Professor of Bioengineering at Harvard SEAS.

The results have been published online in the journal Advanced Materials.

Here's a short video about the process: